Winning Brands has been catching-up to back orders.

For the past several months COVID-19 had been affecting supply lines for some production materials. COVID had also affected our retailer operations. Store hours were reduced in some cases, and government limitations were placed on the number of customers who could be in the store at once. We have been overcoming these issues, as described below.

As far as manufacturing inputs are concerned (such as primary raw material feed stock, finished bottles and finished closures for example) the largest organizations have priority access to any materials that happen to be in short supply. Smaller organizations scramble to compete for whatever is not tied-up by industry giants under contract. Nonetheless, Winning Brands has been able to normalize its supply chain elements gradually. That is why we have been able to begin catching-up to backorders and pick-up the pace of deliveries.

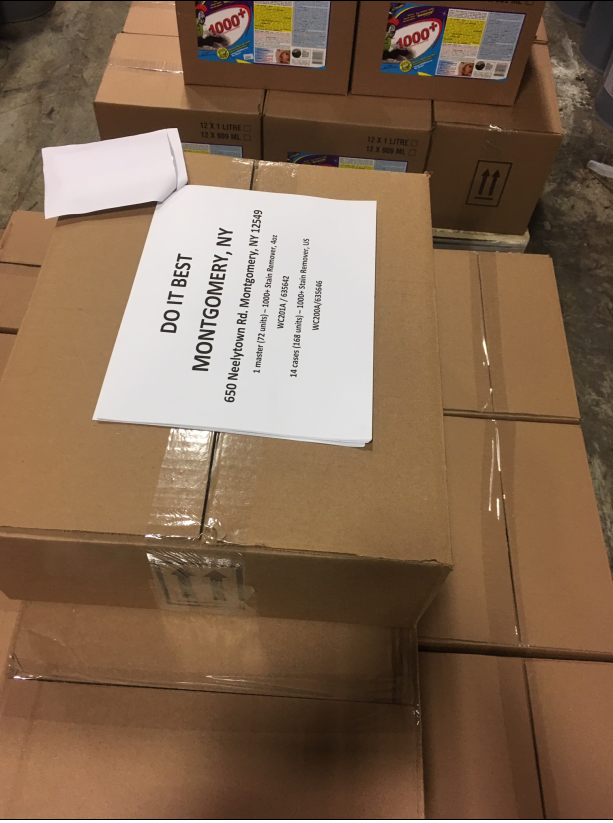

It would be unwise for competitive reasons, and impractical, for me to post here every time a shipment is made. However, doing so occasionally to illustrate that things are moving, and to give you a mental picture, is fine. In this post I am providing more detail about Friday Dec 4th, for example, including some photos and a brief clip of goods being loaded into transport.

The primary task of the day was to stage 5 special skids of mixed SKUs for Do it Best, a hardware store cooperative that operates slightly over 3,000 locations in the USA. They also have affiliates in some countries internationally.

It was encouraging to get these 5 skids ready on Friday because this is part of our pledge to Do it Best to supply 6 distribution centers with product under a new Flooring Department initiative on a timely basis. The 6 centers are in Lexington, South Carolina; Montgomery, New York; Medina, Ohio; Mesquite, Nevada; Sikeston, Missouri and Woodburn, Oregon. The Oregon shipment left the previous day.

In addition to the 5 shipments to Do it Best, we also succeeded in completing a sixth shipment on Friday to top-up our distributor to Lowe’s Canada, making 6 dispatches in total for the day, Friday.

Background

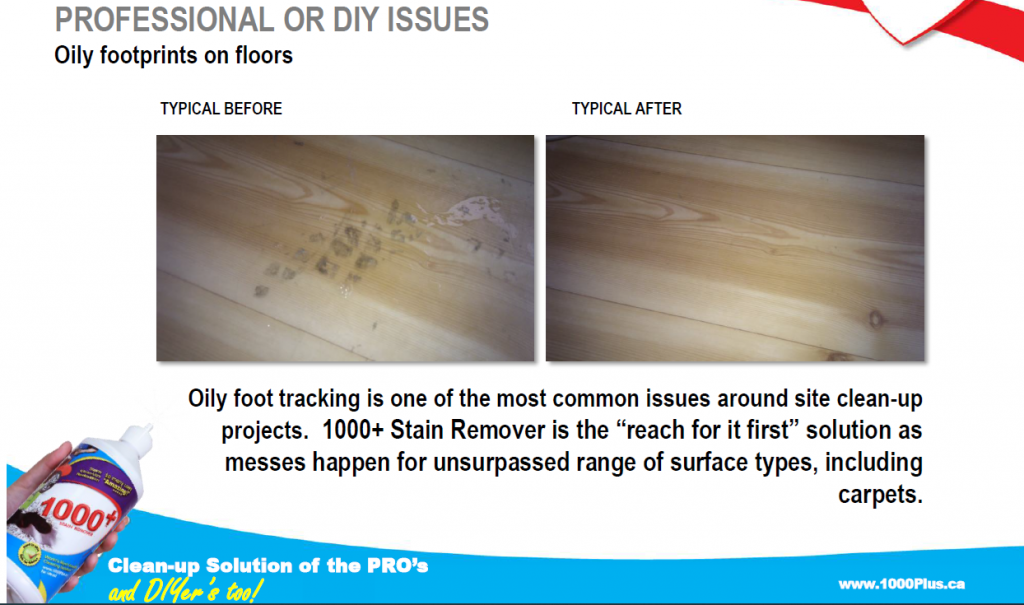

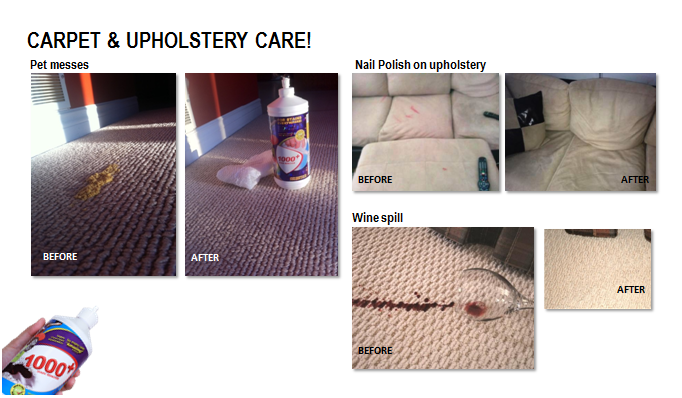

Winning Brands is participating in a Do it Best USA category solutions program in the floor care section. Its purpose is to make new Do it Best corporate planogram proposals to participating Do it Best stores and thereby offer an updated “complete solution” to those stores. Typically this involves various stock-keeping-units (SKU). These proposed offerings are accompanied by initial discounts (by the supplier) to the organization in order to compensate participating stores for having to reset their plan-o-gram section with the new items selected. 1000+ Stain Remover has won the opportunity to be one of those products. Winning Brands won approval on the merits of 1000+ Stain Remover as a floor care solution, even though 1000+ is capable of being in several sections. It’s that versatile. This floor care program will run for about a year. Hopefully, by expiration, we will have gained a permanent presence in an expanded number of Do it Best affiliated stores in America.

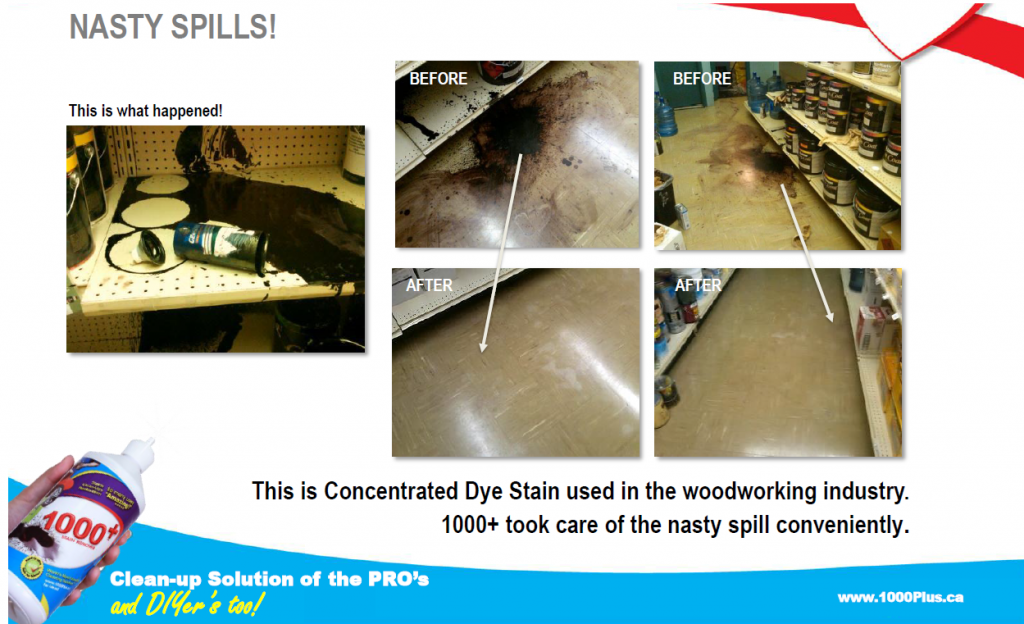

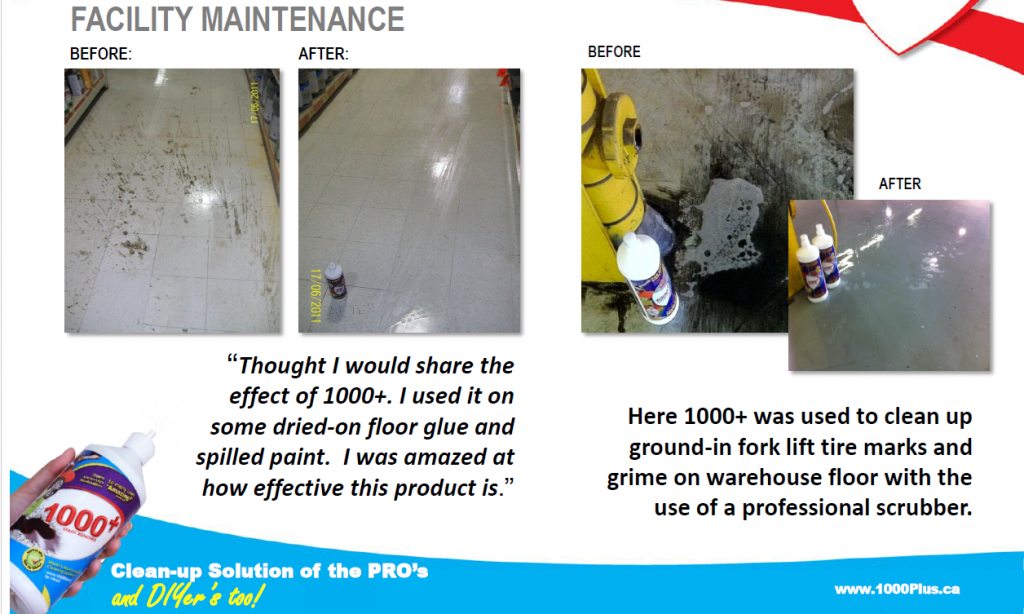

Winning Brands sought this opportunity for several reasons. Floor care is a high value section, where participating products are more than just ordinary generic cleaners by nature. Also, floors receive more spills and messes than any surface, long term. Furthermore, this program is an opportunity for joint initiative with Do it Best corporate category planners. Working together is more fruitful than a basic “buy/sell” relationship.

The in-store placement categorizations are not rigid. A participating store still has the freedom to a place 1000+ in additional sections within the store.

The graphics below illustrate Winning Brands’ positioning of 1000+ Stain Remover in flooring applications.

The exciting thing for Winning Brands in the shipments to Do it Best is not the size of each shipment – these skids were minimum order quantities of slightly over $1,000 each. It is the fact that these orders were received for multiple distribution centers at once. This is proof to me that participation in the floor care initiative is gaining traction across America, not just in a single region. The orders prepared on Friday reflect store requests. These are not goods merely being ordered by Do it Best corporately to hold long term. The minimum orders constitute a Do it Best “just in time” calculation of what they need right now. If the program gains momentum, the average order size will increase.

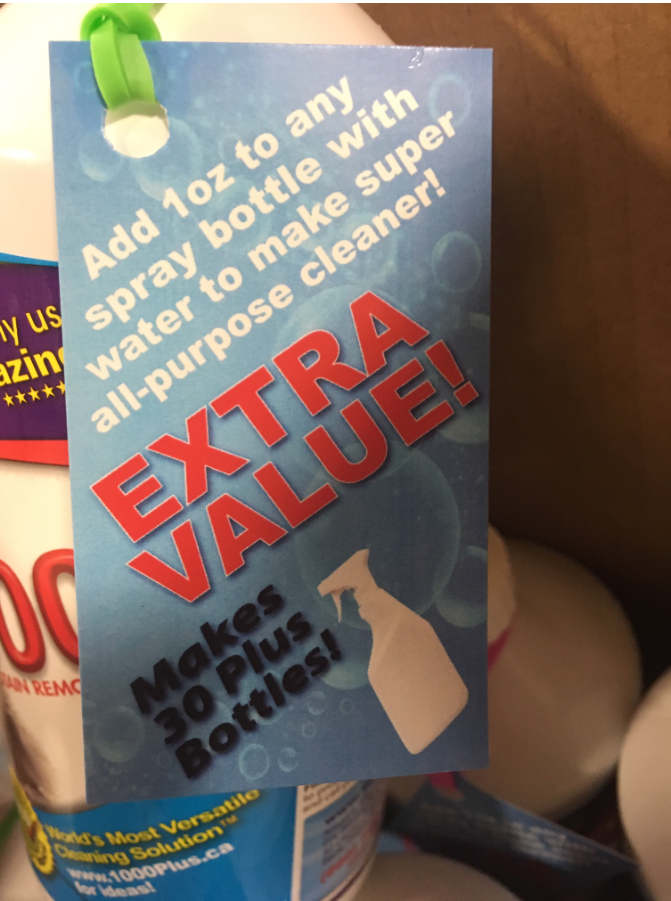

All outgoing 1000+ bottles in the 30oz size now have the new neck tag encouraging consumers to discover using 1000+ as a re-usable spray refill too. This is a new policy. We are micro-targeting neck tags to be relevant to the circumstances of our retailers. We have the flexibility of applying differing messages as required.

Brief video of Dec 4th 2020 shipping of 1000+ Stain Remover at Twitter. The video has sound, so remember to un-mute the player when you get there: https://twitter.com/WinningCEO/status/1335786752838144002